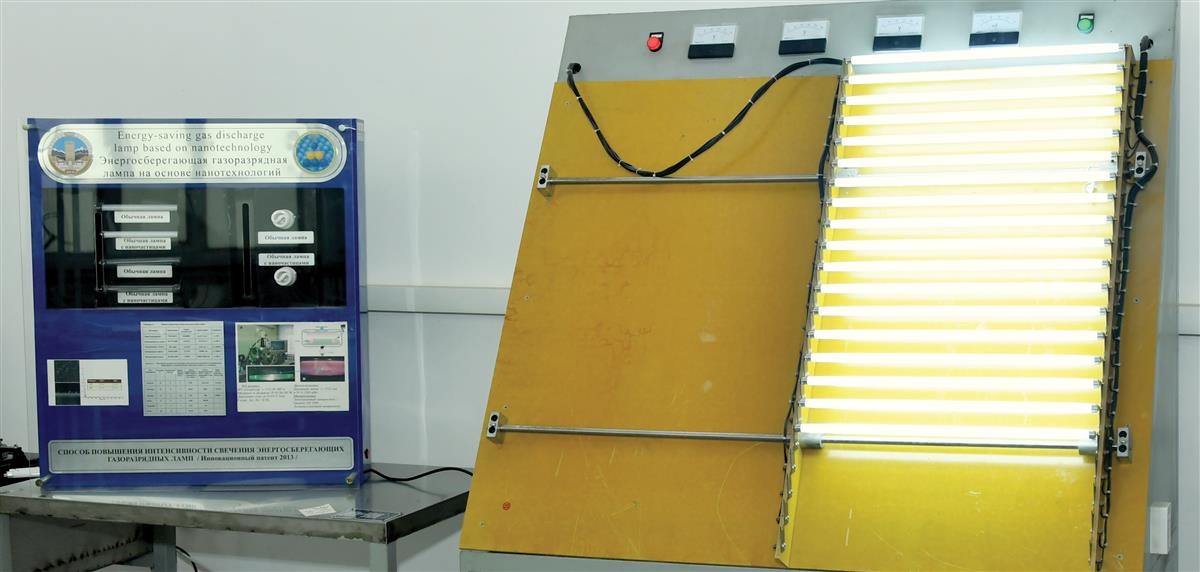

Scientists of KazNU named after Al-Farabi have developed a unique technology for increasing the intensity of the glow of gas-discharge lamps based on nanotechnology, which has a low cost and high quality. Moreover, the intensity of the glow of the developed lamp is one and a half times greater than that of similar fluorescent lamps with equal power consumption, which was confirmed during laboratory tests.

With the development of civilization, the demand for all types of energy is growing from year to year. Due to the increase in energy consumption and the reduction of natural resources, the tariff for electricity is constantly growing. Increasing energy efficiency at the household level and energy saving depend on each consumer individually, however, scientists are actively involved in solving this problem. For example, scientists from the Al-Farabi Kazakh National University have upgraded the manufacturing technology of an economical lamp and developed a new model of an energy-saving lamp. Its main feature is to improve the technical characteristics of a fluorescent lamp with the help of nanotechnology.

The economical lamp was made at the National Laboratory of Nanotechnology of the open type at KazNU named after Al-Farabi. According to the project manager, Candidate of Physical and Mathematical Sciences, laureate of the State Prize of the Republic of Kazakhstan Merlan Dosbolaev, there are no significant changes in the technology - there is no lamp manufacturing. The main thing is to use energy resources efficiently. According to him, the first project was presented in 2011 at a scientific seminar led by Academician Tlekkabyl Ramazanov.

– Our laboratory is engaged in the study of plasma physics and technology. Plasma can be obtained in different conditions. The most suitable laboratory plasma is obtained in a gas discharge. A gas discharge is the passage of an electric current through a gaseous medium. The plasma of the gas discharge formed at this moment gives light. The result of our work was an increase in the intensity of discharge illumination and the creation of energy-saving lamps of a new type. There are several types of electric lamps. For example, due to the fact that a classic type lamp consumes a lot of electricity, we do not currently use it in everyday life. Such lamps spend only 15-20 percent of the energy coming to them on light, the rest goes to heat. Then gas discharge lamps appeared. It spends 60-70 percent of its energy producing light. The third is LEDs, which are currently widely used. They consume 80-90 percent of the energy for light, but quality samples are very expensive. The electric lamp manufactured by us belongs to the type of gas discharge lamps. The peculiarity of these lamps is their increased light transmission,” says project manager Merlan Dosbolaev.

Scientists note that when studying various physical properties of gas discharge plasma in the laboratory, introducing micro-, nano-particles into the composition, their light emission increases several times. In a word, the light output of the gas discharge is increased without changing the power consumption.

“With the same energy consumption under laboratory conditions, the light intensity of the gas discharge plasma containing nanoparticles has doubled,” says Merlan Dosbolaev. – Later, the idea arose to create a new version of gas-discharge lamps based on nanotechnology. Based on the results of these studies in 2012-2013, we published scientific articles in journals such as Physics of Plasmas, CPP. Then they took part in the Science Foundation competition, where they received a patent for this novelty. Today we are engaged in the production of this project on a grant from the Science Foundation. It should be noted that for the effective operation of LED lamps, expensive technologies are needed. Most of these lamps, which are now on store shelves, are made from inexpensive materials. You know, quality products are expensive. In this regard, our lamps are much cheaper than on the market.

Postdoctoral student of KazNU and senior researcher of the Institute Sagi Orazbaev spoke about another advantage of this lamp. According to the scientist, the old lamps in the event of a breakdown caused a certain amount of radiation. The lamps made by the university specialists use amalgam instead of mercury. “We know that this element has a negative impact on human health. From a safety point of view, amalgam is a very effective solution. We can say that we removed mercury altogether, but delivered as little as possible. They replaced it with a mixture of mercury and metals - amalgam. In the future, we are considering ways to completely remove it,” says the young scientist. Amalgam is the combination of a small amount of mercury with other metals. Thus, it is part of the gas discharge, changing the spectrum of light and increasing its intensity.

The fourth state of matter is plasma. We noticed that when nanoparticles are introduced into its composition, the light intensity increases several times. We have published articles about this in high-ranking foreign journals. Representatives of the foreign scientific community reacted positively to them. Hence the idea arose of how we will use this phenomenon. Inside the plasma there is a so-called dusty plasma. This is a buffer (pure) plasma with monodisperse particles within micro-, nano-sizes. If you burn the plasma with inert gases, you can get a pure plasma. If we add only a few reactive gases to these inert gases: methane, silane, acetylene, etc., then nanoparticles can be obtained. In this case, the light intensity of the plasma increases several times. Currently, fluorescent lamps (a type of gas discharge lamp) and LED lamps are leading the market for energy-saving lamps. And another species that has not yet reached our country is an induction lamp. It is also made on the basis of a gas discharge lamp. It is most used in America, Canada and some European countries. The efficiency of these lamps is very high, says Sagi Orazbaev.

The applicant underwent a scientific internship at the Orleans Polytechnic University of France. In the same place, he was able to fully study the effect of increasing the intensity of light and determine how the light intensity changes with the size of the nanoparticles. The innovators received a patent in 2013-2014. As a result, a new high-intensity nanoparticle gas-discharge lamp was created. This project won first place at the university, and also in the same year won the nomination for the best social project in the Business Forum Almaty project. Currently, there are many types of products on the market for energy-saving lamps that meet your request. But now, adhering to the principle of an open economy, you can find both high-quality and low-quality things on the market. This also applies to LED lamps. At present, the average consumer pays great attention to the price, giving preference to low-quality, cheap goods. But, it must be taken into account that low-quality LED lamps create linear spectra that are harmful to the eyes.

“When using LED lamps, the light intensity is transmitted linearly,” explains Sagi Orazbaev. – It is harmful to the eye, damaging certain capillaries responsible for the wavelength of the eye. From such light, the eyes are prone to diseases such as color blindness, night blindness. This has been scientifically proven by the world community. Korea and Japan were the first to use these LED lamps. It is known that the primary cause of eye diseases is just such a lighting system. The human eye is accustomed to a natural light source. Light bulbs with thin tungsten spirals are more like natural light from the su's rays. But they take a lot of energy. The next approach to natural light is fluorescent and induction lamps. Initially, this lamp also had many shortcomings. But over time, as a result of various studies, it was possible to remove them. Currently, LED lamps are being created using modern technology with the installation of special lenses, they are closer to natural light. To make the light of the linear spectrum look like natural sunlight, you need to use different focusing lenses. This is an expensive technology. Therefore, the price of such lamps will not be low. In this regard, the price of high-quality LED lamps remains high.

Speaking about the price, it is impossible not to dwell on the cost of production, production processes. According to Sagi Orazbayev, the production of the necessary raw materials for the lamp - glass, electrodes, necessary electrical products - has not yet been established in our country. “Despite the fact that we have intellectual property, most of the raw materials for production have to be obtained from countries such as Russia, China,” the scientist says.

Scientists of KazNU successfully completed the project in three years. According to Mukhit Muratov, director of the National Nanotechnology Open Laboratory, the next task is to sell products.

– We are considering the possibility of participating in public procurement tenders. In the future, we plan to sell 100 thousand pieces per year. Currently, educational institutions and government institutions such as universities, schools, colleges are interested in them. Many of these organizations have installed gas-discharge fluorescent lamps. Replacement costs a lot. And it is much more profitable for consumers to install our economical gas-discharge lamp. At present, we have installed energy-saving lamps of our own invention in the building of the Faculty of Physics and Technology of our university. In the future, it is planned to use energy-saving lamps invented by KazNU scientists on all buildings of the educational institution. Thus, we are confident that the project will reach the payback level in three years, - the head of the laboratory spoke about future plans.

The weekly production capacity of the economical lamp manufactured at the National Laboratory of Open Type Nanotechnology at Al-Farabi KazNU is about 3,000 units, and to date, 50,000 units of T5 and T8 lamps have been manufactured through small-scale production.

Kairzhan TUREZHANOV