Today, the Faculty of Chemistry and Chemical Technology of Al-Farabi Kazakh National University is implementing several projects that stand out among the world's innovative technologies. When you see the activity and enthusiasm of young scientists working on these projects, you need a glass, you feel warm. You believe in the future of Kazakhsta's science. Sometimes you think that if such research was conducted abroad, investors who noticed its value, efficiency and benefits would invest in it and try to commercialize it in the market.

There are also projects in our country, but it is no secret that they are few. We interviewed Meruert Nazhipovna, the head of the project "Obtaining fibrous composite materials by electrospinning and making electrodes for supercapacitors based on them."

Wood chips are a cheap raw material

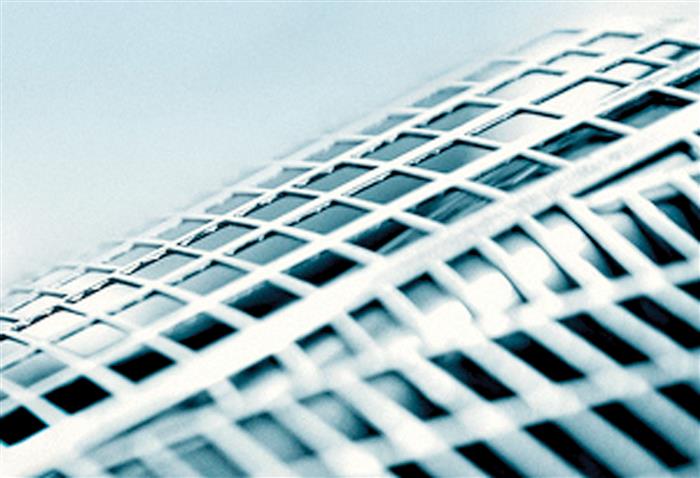

This project can be a priority for the efficient use of natural resources, including water resources, geology, processing, new materials and technologies, safe products and structures. The idea of the project is to obtain composite materials by the method of electrospinning with the required properties, using them as electrodes for supercapacitors.

- We set a goal to develop the synthesis of composite materials of the required length, diameter and porous lignin fiber with a variety of nanoparticles and on their basis to create high-capacity electrodes for supercapacitors. Thus, we study the conditions for the synthesis of lignin from wood waste, and work out the synthesis of fibrous composite materials by electrospinning. In particular, we are working on the design of the device, determining the distance between the polymer, solvent, electrodes, selecting and studying the magnitude of the voltage depending on the type and size of the obtained fiber composite materials, "Meruert Nazhipovna told us.

Scientists around the world are now using any polymer to obtain different fibers. They often use ready-made lignin for such work. It will be expensive. “Initially, we wanted to dispose of all kinds of waste. What's more now - a lot of sawdust. We cannot say that all the waste from construction and furniture production is processed or recycled. So instead of buying lignin, we decided to get it from sawdust. We chose pine and elm sawdust for it. For example, in order to compare our composition and properties, we also ordered ready-to-use lignin for this project. We paid for it in advance, 3-4 months have passed and we still have't received it. We ordered it abroad. It was supposed to come from China or Europe, but we do't know yet. You see, it is difficult for the finished product to arrive on its own, so it would be great if we could produce it ourselves in the future, ”said the young scientist.

What is lignin?

Lignin is a complex three-dimensional linear polymer that ranks second only to cellulose. A mixture of chemically compatible aromatic polymers with lignin. It is obtained from biomass sources. The composition, quality, formula, chemical and physical characteristics of lignin depend on the source of biomass. The advantage of lignin is that it is an environmentally friendly product, which is both cheap and affordable.

Ability to make capacitors and batteries

According to Meruert Nazipovna, the process of synthesis of lignin fiber composite materials by electrospinning allows to obtain various modified and dimensional materials. Polymer precursors are usually used as a basis for the production of nanofibers. “In our work, lignin, which replaces the expensive polymer, is synthesized from unclassified wood chips. Fibrous composite materials are synthesized by introducing various nanoparticles into primary precursors. They determine the further application of the obtained material (for example, carbon nanotubes must be added to the polymer wires to obtain a conductive material, etc.). The obtained composite material is sent for processing if necessary. For example, it is sent for incineration in the presence of carbon or inorganic nanofibers, "said Meruert Nazhipovna.

In addition, the project provides for the production of composites based on them by electrospinning and working out the mode of synthesis of the required length, diameter, and porous nanofibers. When conducting a comprehensive study in the field of synthesis of fibrous composite materials, their physicochemical, ie mechanical, catalytic, electrical, etc. It is planned to determine the properties, as well as predict the structure. The obtained materials are used to make fibrous composite materials and energy storage devices. For example, they can be used to make capacitors and batteries. Clearly, comprehensive research in the field of production of lignin nanoparticles and composites based on them and the synthesis of fibrous composite materials will allow the creation of energy-saving devices, capacitors and batteries.

Novelty of the project

Now let's talk about the novelty of this work. It is known that any research work is new. For the first time, young scientists intend to obtain lignin fibers from unclassified wood chips by electrospinning. Wood waste and shavings are used as raw materials. The research is worth it. Polyacrylonitrile (PAN) is commonly used to obtain fibers. It is very expensive and its removal requires additional material costs. The main difference from previous studies is that the synthesis of lignin from wood waste is based on the production of nanoparticles by electrospinning in order to form structures with the required physical and chemical properties.

Experiments are also being carried out to make electrodes for supercapacitors with high specific properties. In the project, lignin is synthesized from unclassified wood chips by the organosolv method. Synthesized lignin is used to make nanoparticles. Unlike the known methods of lignin extraction and the method of obtaining cheap electrically formed fibers, this method of lignin synthesis allows to obtain continuous fibers with a nanoscale diameter. Therefore, this method is cost-effective and simple, and does not take much time.

Summary

If the project is implemented, first of all, it will be possible to enter the world high-tech market by the method of synthesis of fibrous composite materials by electrospinning to obtain new products for various functional purposes. Secondly, prerequisites will be created to increase the competitiveness of the country's economy. Third, the results of the research can be used by companies specializing in the development of new nanomaterials with improved mechanical, electrical and thermophysical properties, as well as companies engaged in the development of power supply elements, nanoelectronic devices, and biosensors.

This year Meruert Najipovna trained at Eskisehir Technical University in Turkey in the field of nanotechnology. "The state supports young scientists and allocates millions from the budget. Young people who go abroad should gain in-depth experience and enrich their professional skills. Is't it a great opportunity to get acquainted with modern advanced technologies, to see how new projects and developments related to your research work are created and implemented? When I go to exchange experiences, I spend all my attention and enthusiasm on education and professional development, I do not want to waste my time. I travel around the country only on weekends, the rest of the time I will be in the research area of the university, "said Meruert Nazhipovna.

Gulzat NURMOLDAKYZY